Automatic Winding Machine Used in Industry

The full-automatic coil winding tin-dipping production line is mainly composed of three parts: automatic terminal insertion machine, automatic winding machine and automatic tin-dipping machine. It is a full-automatic winding machine integrating automatic feeding, automatic winding, automatic feeding, automatic blanking, adjustable spindle speed and adjustable number of windings.

MessagesProduct Details

Function and Advantage

The full-automatic coil winding tin-dipping production line is mainly composed of three parts: automatic terminal insertion machine, automatic winding machine and automatic tin-dipping machine.

It is a full-automatic winding machine integrating automatic feeding, automatic winding, automatic feeding, automatic blanking, adjustable spindle speed and adjustable number of windings.

The equipment adopts PLC touch screen operation, and the steps are simple and easy to learn.

High operating efficiency, good stability, widely praised in the industry

Product Parameters

| Equipment air source | 0.4-0.6Mpa |

| Power | 4kw |

| Efficiency | 1000-1200 pieces/hour |

| Power supply | AV380v,50Hz |

Product recommend

Large American Type Hose Clamp Automatic Assembly Machine

The equipment completes the automatic production of American hose clamp

Small American Type Hose Clamp Assembly Machine

The equipment for the American throat hoop assembly machine after the broken roll round on the screw.

German Type Hose Clamp Automatic Assembly Machine

The equipment is used to complete the German-style throat band automatic winding round

British Hose Clamp Automatic Assembly Machine

This equipment is used for automatic assembly of English throat hoop screws

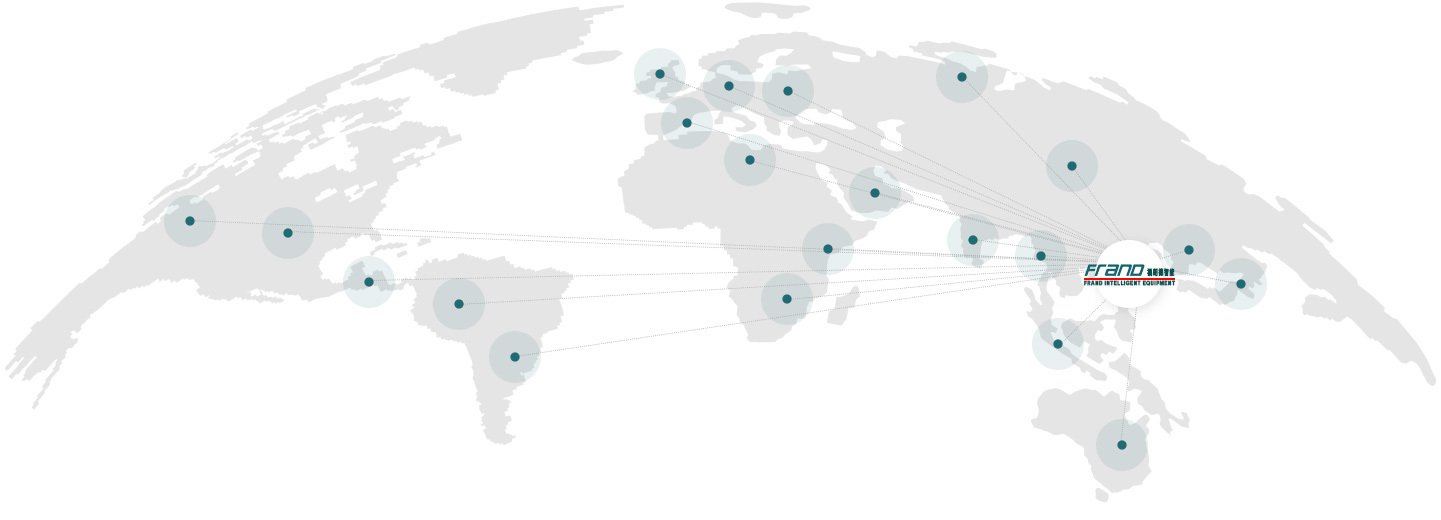

Products have been all over the country, and exported to Japan, Thailand, India, Brazil, Russia, Southeast Asia and more than 100 countries and regions, well received by customers.

Jiapin Industrial Park, 130 Guankou Middle Road, jimei district, Xiamen City

Jiapin Industrial Park, 130 Guankou Middle Road, jimei district, Xiamen City gavin@frandchina.com

gavin@frandchina.com